Technical information

Introduction video

[high resolution] It is hard to see it and is the world of clearance 2μm! Please confirm a high metalwork technology of the Cam.

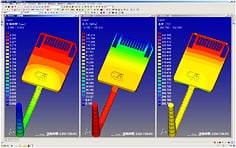

Design

From an order to product shipment

STEP1 estimate ... design design

After having had an estimate, I perform a summary design.

If an order is settled, I make arrangements with a customer in a member of our business, technical people and perform details design (design design). At the same time, I flow based on 3D data having you provide it from a customer and can analyze it.

If an order is settled, I make arrangements with a customer in a member of our business, technical people and perform details design (design design). At the same time, I flow based on 3D data having you provide it from a customer and can analyze it.

STEP2 die design / die production

I perform die design - die production based on a design design.

I utilize the specialized base (home and abroad) of our group to the full and offer the best die in deadline, cost, quality, all.

I utilize the specialized base (home and abroad) of our group to the full and offer the best die in deadline, cost, quality, all.

STEP3 trial manufacture - mass production

I ascertain the most suitable molding condition for a stable mass production and I perform a trial and submit an authorized sample and measurement data.

I do mass production - shipment in the production base that I decided at the time of an order after a customer gave product authorization to me.

I do mass production - shipment in the production base that I decided at the time of an order after a customer gave product authorization to me.

Design design

●Basic design about a die, the molding to make a product with the most suitable state

I make out the schedule for a schedule before having the authorization of the end product after receiving the firm order from a customer.

Then, I work out a basic design about the structure of the die to make a product with the most suitable state and I make the specifications which included a gate method, a product takeoff method, cavity runner placement and direct the die design section which is the next process.

Then, I work out a basic design about the structure of the die to make a product with the most suitable state and I make the specifications which included a gate method, a product takeoff method, cavity runner placement and direct the die design section which is the next process.

One special structure by the design design of the die

Colla psi bulldog core

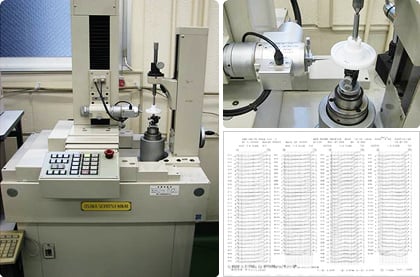

Optical component measuring equipment

Gear evaluation apparatus

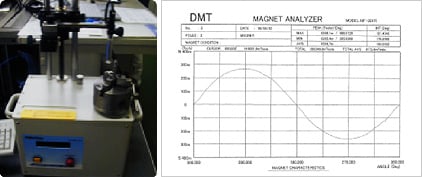

Magnetometry apparatus

Molding system

The quality of the cast depends on the stability of the molding process. The Cam watched the abnormality of a molding condition and neighboring facilities and developed the system which could stock only the OK quality in the set point for 48 hours. This system (Cam stocker) lays the foundation of the unmanned consecutive operation and PPM guarantees of quality in the Cam.